TOFD SCANNER

Time of Flight Diffraction

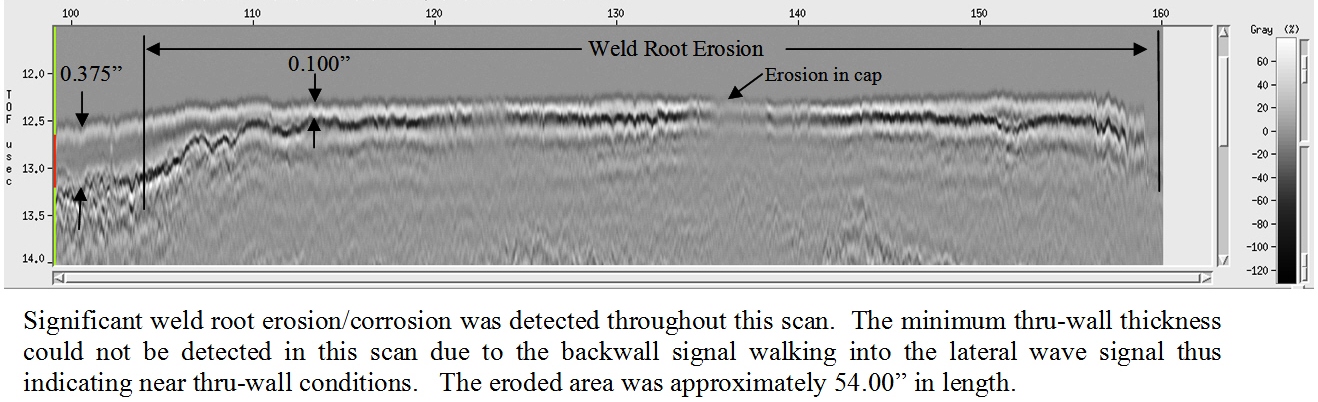

Time of Flight Diffraction or TOFD, is one of the most promising ultrasonic techniques for the examination of welds on pressure vessels in lieu of radiography; for pipe weld quality or crack detection and also weld root erosion. TOFD is a computerized ultrasonic system able to scan, store, and evaluate indications in terms of height (through wall thickness), length and position, with a degree of accuracy and speed never achieved with other ultrasonic techniques.

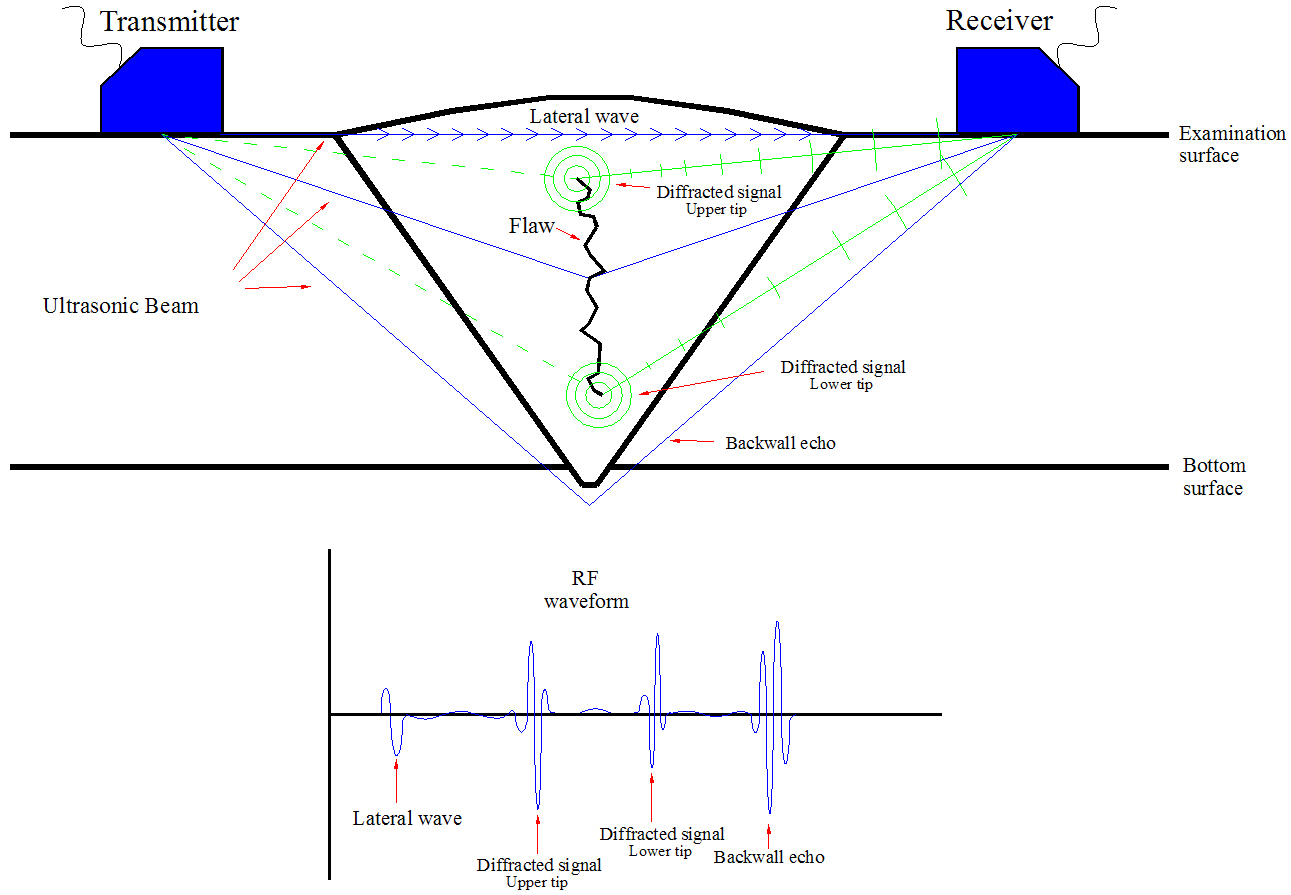

Theory – TOFD consists of a separate ultrasonic transmitter & receiver. The probes are aimed at the same point in the weld volume. The entire weld is then flooded with ultrasound allowing inspection of the weld. After emission of a compressional wave from the transmitter, the first signal to arrive at the receiver is the lateral wave or OD wave which represnts the outer surface or OD. In the absence of defects, the second signal to arrive at the receiver is the L-wave backwall echo which represents the inner surface or ID. When a flaw is present, a diffracted signal is generated at the upper tip of a defect and will arrive before the signal generated at the lower tip of a defect. With a time of flight of each flight path, ultrasonic velocity and the spatial relationship of the two probes, the location and height of the defects can be accurately calculated. Gray scale imaging techniques are applied to the RF (AC) signal phase and enables weld integrity to be observed in real time.

The American Society of Mechanical Engineers (ASME), through Section VIII, implemented the use of TOFD in the Boiler and Pressure Vessel code. The purpose of this was to allow ultrasonic examinations on welds greater than 0.500″ in thickness in lieu of radiography. The downside to radiography, especially of heavy wall materials, is its long shot time. This results in hours of down time due to its radiation zone, thus causing a loss of production. Ultrasonic scanning can be performed in a matter of minutes, which does not stop production, and is environmentally safe. Other advantages are: fast, accurate, repeatable, full volumetric inspection, and data electronically recorded and saved.

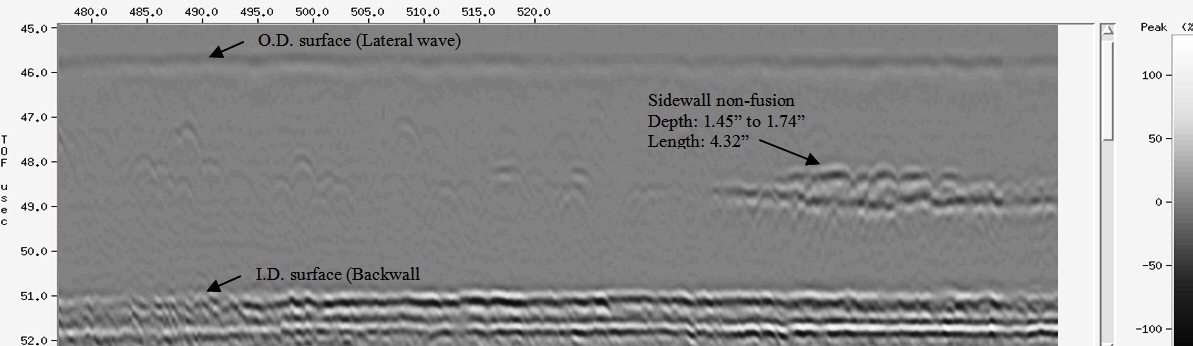

TOFD is also an excellent tool when detecting service related cracking, especially on components in cyclic service such as Coke Drums, PSA Vessels, Compressor Tanks, etc. TOFD can also be utilized on newly constructed pressure vessel welds after post weld heat treatment for the purpose of detecting post stress cracking.

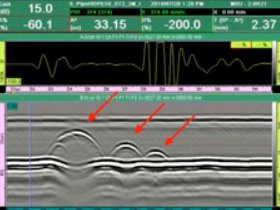

TOFD Scan on a Coke Drum Weld with multiple I.D. cracks present

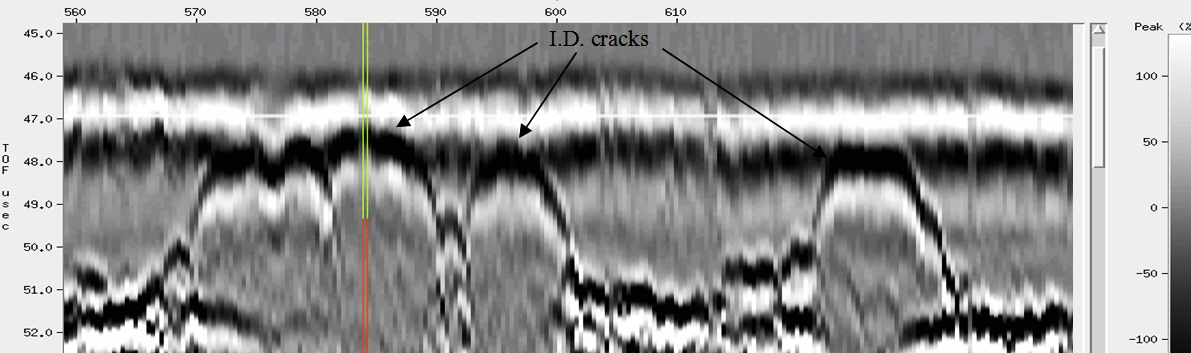

TOFD can also be utilized in Weld Root Erosion Detection.

TOFD Scan on a 0.375″ thick Vessel Weld with Weld Root Erosion present

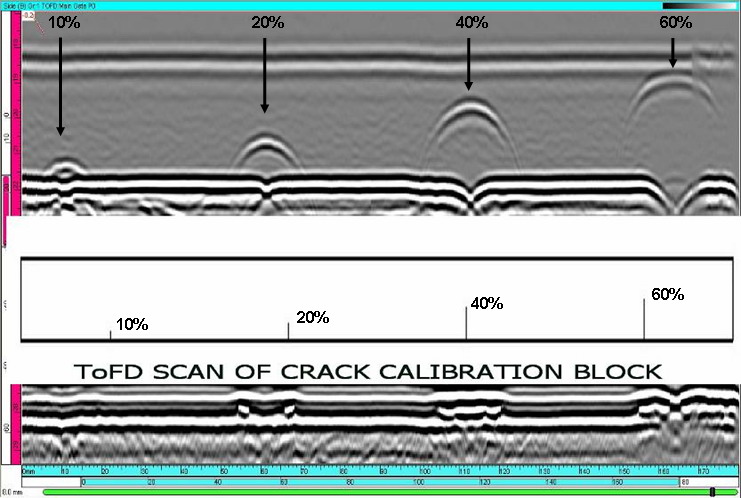

TOFD sizing accuracy and detectability is phenomenal (Below are images of TOFD on ID notches and side drilled holes)

ID Notches

ID Notches

Please enter your info and we’ll send you a link to download your PDF.

Please enter your info and we’ll send you a link to download your PDF.